External Circlips

NWB supply a range of Circlips of Interal or External Type.

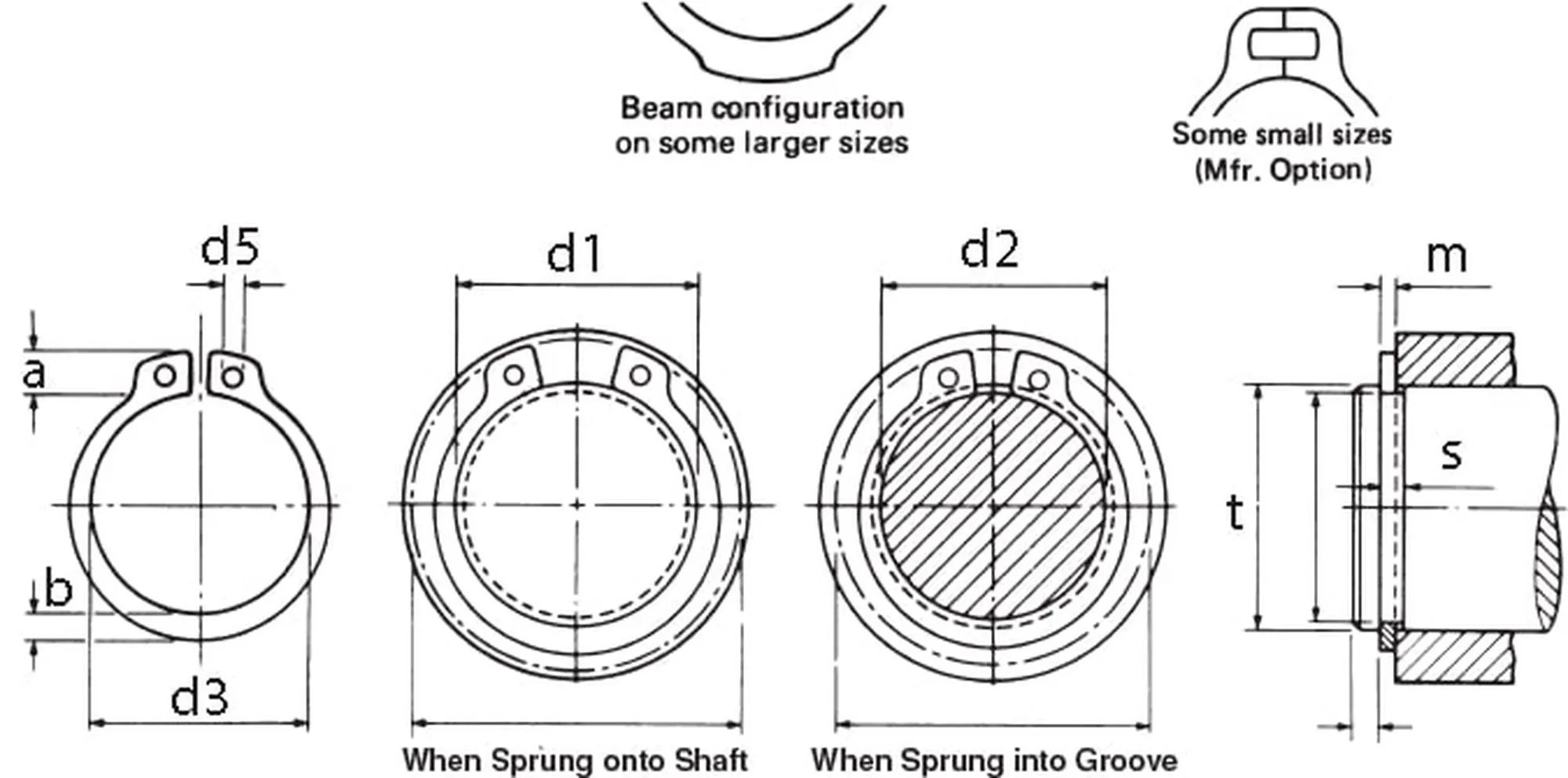

A circlip is a type of retaining ring or fastener that takes the form of a flexible, open-ended ring, made from metal. They are also known as retaining rings, snap rings or c-clips. Circlips are often used to secure pinned connections.

There are 2 basic designes of Circlips:

Internal circlips

External circlips

External circlips fit around the shaft, pressing on it. Each opposing end of the ring will have a lug with a small hole through it. These holes are where the tips of circlip pliers can fit to remove or install the circlip, contracting the external circlip to fit in the groove around the shaft, or expanding the circlip to remove it from the shaft.

There are many variations of external circlip design, as they are used for many applications.

NWB are accredited to ISO 9001, 18001 and 45001 and follow strict quality processes to ensure our customers receive the highest level of service and quality.

If you would like to discuss your External Circlip requirements with us directly please call our sales line on 01302 330366 or email your details to us along with your requirements and we will get back to you with a proposal. Similarly, if you need help identifying your external circlip please contact us and we will be happy to help.

Suitable For

| McHale |

| Massey Ferguson |

| Land Rover |

| CNH |

| Maschio |

Features

| d2 Tolerance (mm) | -0.04 |

| s Tolerance (mm) | 0.1016 |

| d3 Tolerance (mm) | -0.1778 |

| d2 Tolerance (mm) | -0.0254 |

| s Tolerance (mm) | 0.0762 |

| d3 Tolerance (mm) | -0.127 |

| d2 Tolerance (mm) | -0.0508 |

| s Tolerance (mm) | 0.0508 |

| s Tolerance (mm) | 0.127 |

| d3 Tolerance (mm) | -3.556 |

| d2 Tolerance (mm) | 0.2032 |

| d3 Tolerance (mm) | -0.762 |

| d2 Tolerance (mm) | 0.1778 |

| d3 Tolerance (mm) | -0.508 |

| d3 Tolerance (mm) | -0.254 |

| d2 Tolerance (mm) | 0.1524 |

| d2 Tolerance (mm) | 0.127 |

| d2 Tolerance (mm) | 0.1016 |

| d2 Tolerance (mm) | 0.0762 |

| d2 Tolerance (mm) | 0.0508 |

| d3 Tolerance (mm) | -0.0762 |

| d3 Tolerance (mm) | -0.0508 |

| d2 Tolerance (mm) | 0.0381 |

| s Tolerance (mm) | 0.0254 |

| s Tolerance (mm) | -0.1 |

| d2 Tolerance (mm) | -0.35 |

| d3 Tolerance (mm) | -0.76 |

| d3 Tolerance (mm) | -0.64 |

| d2 Tolerance (mm) | -0.3 |

| s Tolerance (mm) | -0.08 |

| d3 Tolerance (mm) | -0.51 |

| d2 Tolerance (mm) | -0.25 |

| s Tolerance (mm) | -0.07 |

| d3 Tolerance (mm) | -0.25 |

| d2 Tolerance (mm) | -0.21 |

| d3 Tolerance (mm) | -0.21 |

| s Tolerance (mm) | -0.06 |

| d2 Tolerance (mm) | -0.13 |

| d2 Tolerance (mm) | -0.11 |

| d3 Tolerance (mm) | -0.26 |

| s Tolerance (mm) | -0.2 |

| d3 Tolerance (mm) | +2.00/-4.00 |

| d2 Tolerance (mm) | -1 |

| d3 Tolerance (mm) | +1.50/-3.00 |

| s Tolerance (mm) | -0.15 |

| d3 Tolerance (mm) | +1.00/-2.00 |

| d3 Tolerance (mm) | +0.90/-2.00 |

| d2 Tolerance (mm) | -0.89 |

| d3 Tolerance (mm) | +0.81/-2.00 |

| d2 Tolerance (mm) | -0.81 |

| s Tolerance (mm) | -0.12 |

| d3 Tolerance (mm) | +0.70/-1.70 |

| d2 Tolerance (mm) | -0.72 |

| d3 Tolerance (mm) | +0.63/-1.50 |

| d2 Tolerance (mm) | -0.63 |

| d3 Tolerance (mm) | +0.54/-1.30 |

| s Tolerance (mm) | -0.05 |

| d2 Tolerance (mm) | -0.54 |

| d3 Tolerance (mm) | +0.46/-1.10 |

| d3 Tolerance (mm) | +0.39/-0.9 |

| d3 Tolerance (mm) | +0.25/-0.50 |

| d3 Tolerance (mm) | +0.21/-0.42 |

| d2 Tolerance (mm) | -0.15 |

| d3 Tolerance (mm) | +0.1/-0.36 |

| d3 Tolerance (mm) | +0.06/-0.18 |

| d2 Tolerance (mm) | -0.06 |

| d3 Tolerance (mm) | +0.04/-0.15 |